Industry news

Crevice corrosion of stainless steel

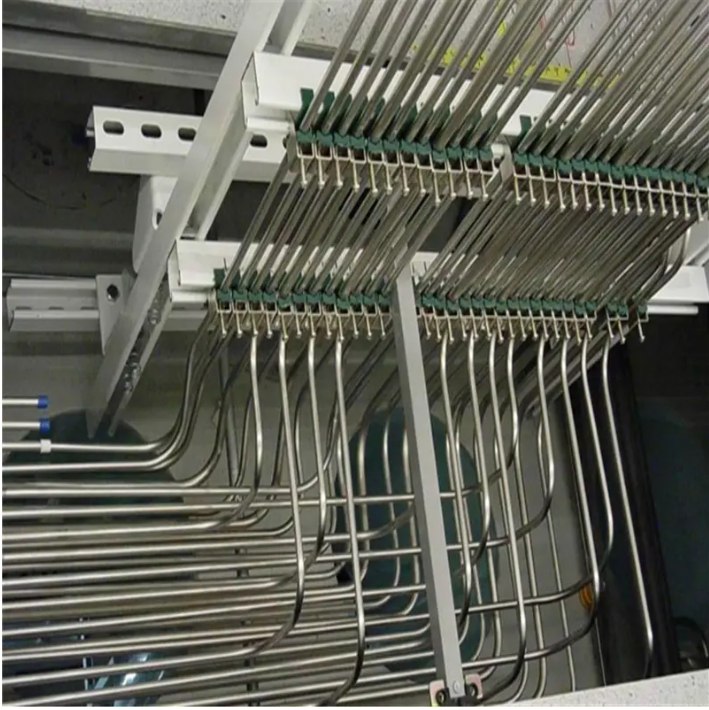

The crevice corrosion of stainless steel is considered as local corrosion. The problem of crevice corrosion mainly occurs in chlorine containing solutions. The joint crevice is wide enough to allow solution penetration, but narrow enough to produce stagnation conditions. Crevice corrosion is most likely to occur in seawater applications.

How to reduce the risk of stainless steel crevice corrosion

Through proper engineering design, the risk of crack corrosion can be reduced or problems can be eliminated. A typical example of a crack is the restricted area associated with and generated by the design of flanges, tube to tubesheet joints, bolt heads to washers, washers to substrates, and threaded connections. The closer the gap is, the greater the risk of crevice corrosion.

Crevice corrosion is the most serious problem in stagnant solution. When the flow rate exceeds 1.5m/s, the risk is reduced because there will be no corrosive environment for sediment formation and accumulation. When the structure requires gaps, it is recommended to use an open design in which the surrounding solution is allowed to flow as freely as possible.

To ensure no crevice corrosion, the design temperature should generally be at least 15-25 ° C (59-77 ° F) below the temperature of the point corrosion hazard.

Stainless steel should not normally be painted as damage to the paint will cause interstitial corrosion.

The mechanism and related problems of crevice corrosion are the same as those of pitting corrosion in many aspects. Therefore, good crevice corrosion is usually accompanied by good pitting corrosion resistance.

Effect of alloying elements

These alloy elements have the following effects on the crevice corrosion resistance of stainless steel materials:

Chromiun(Cr)+

Molybdenum (Mo)+++

Nitrogen+++

Crevice corrosion test

The crevice corrosion test is carried out using sample blocks with crevices. Samples with standardized gaps are preferred to obtain accurate results. For example, a spring loaded slit former.

Brief description of crevice corrosion

Crevice corrosion occurs in crevices and other narrow spaces, mainly in chlorine containing solutions

Solutions that should avoid stagnation; The recommended flow exceeds 1.5 m/s

Through proper engineering design, the risk of crack corrosion can be reduced or problems can be eliminated.

Categories

News

Contact Us

Contact: Stainless steel press fitting

Phone: 0086-15576743338

Tel: 0086-577-86809218

E-mail: jzpu@qq.com

Add: Binhai 15th Road, Wenzhou Economic Development Zone